Infrared Thermal Imaging Inspections

What at Infrared Inspections?

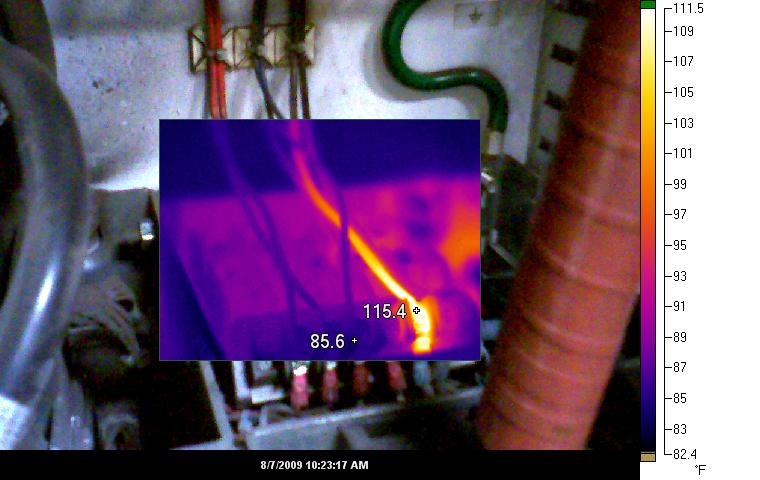

Thermal Electrical Inspections are formed by comparison of temperatures when measured against other temperatures observed in surrounding or similar components. These variations in temperature often reveal some sort of abnormal operation. Temperature abnormalities are often caused by defective or failing components. Concealed equipment problems exist in almost every significant building. Unfortunately, very few are discovered and corrected through conventional maintenance activity. Most go undetected until there is an operating failure. Usually the failure does extensive damage and causes some interruption of operation. Fires and personal injury are less frequent but they can happen. Electrical Thermographic Inspections can catch potential problems before they are ever realized. If done periodically, these predictive thermal inspections can save maintenance cost and prevent unproductive downtime."An Innovative Approach to Preventive Maintenance"

The images in this page were taken by our own Thermography crew. We have found temperature abnormalities in relatively new and well maintained facilities. Our equipment makes a copy of the images associated with temperature abnormalities.How to Determine if You Need a Thermographic Inspection

Could you ever lose production time due to an electrical malfunction? If you could predict the health of your equipment and prevent downtime, would you? If you answer yes to these questions then you have determined that you can benefit from a Thermographic Inspection. While no one can predict exactly when an abnormal condition will cause equipment failure THERMOGRAPHY allows corrective action to be taken in advance.What Else Should I Know?

A Thermographic Inspection is non-contact and is safe to perform on energized electrical systems.

Why Get an Inspection?

Most problems go undetected until there is an operating failure. Usually the failure does extensive damage and causes some interruption of operation schedules. Thermographic Inspections can catch potential problems before they are ever realized. If done periodically, these predictive thermal inspections can save maintenance cost and prevent unexpected downtime.What Electrical Distribution Equipment should have Thermographic Inspections

- Utility substations, transformers and feed poles.

- Power Distribution SystemMain switchboards and disconnects

- Service Disconnects for motors Machine Control Panels