Thermographic Inspections

Thermographic Infrared Inspections

The basis of Thermographic Infrared Inspection is formed by the comparison of temperatures, measured and observed, across surrounding and similar components. These measures are able to catch any variations in temperature, which often reveal defective or failing components.

Concealed equipment problems exist in almost every significant building. Unfortunately, very few are discovered and corrected through conventional maintenance activity.

Most problems go undetected until there is an operating failure. Usually the failure does extensive damage and causes some interruption of operation schedules.

Thermographic Inspections can catch potential problems before they are ever realized. If done periodically, these predictive thermal inspections can save maintenance cost and prevent unexpected downtime.

What Electrical Distribution Equipment should have Thermographic Inspections?

- Utility substations, transformers and feed poles.

- Power Distribution System

- Main switchboards and disconnects

- Service Disconnects for motors

- Machine Control Panels

Included in a Scan:

Infrared scan of components such as: main electrical services, main distribution panels, panel boards, load centers, motor control centers, buss ducts, generators, capacitors, transformers, switch gear, safety switches, motor starters, motors and specialty items at the customer’s request.

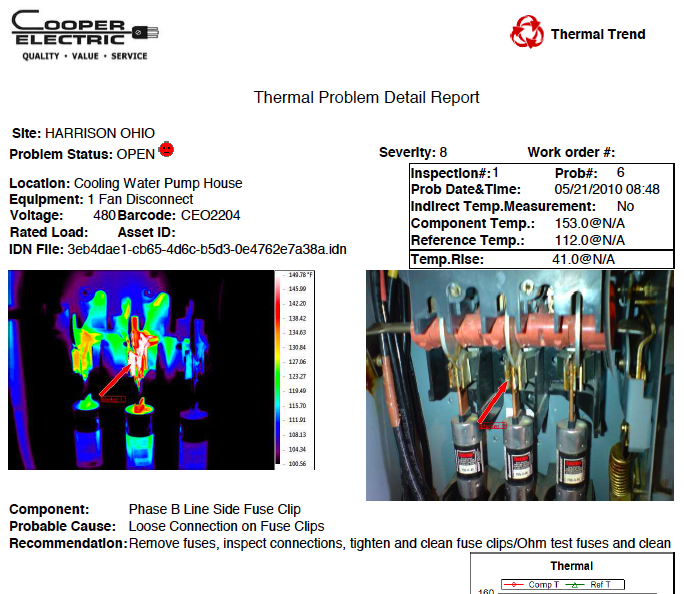

Complete Report

Both an electronic and hard copy report on each component scanned which include thermal image and visual image with temperature measurements and recommended course of action.

High Def Thermal Images

We use a 640 x 480 high definition resolution pro-series camera. Which produces highly precise temperature measurements and images.

Immediate Alerts

Severe or highly critical issues are brought to your attention immediately.

Temperature Trending

Trending information compiled for comparison of scans over time. Where images and measurements are stored for present and future analysis.

Bar Coding Identification

Bar coding is utilized to indentify components and equipment scanned for trending comparison history.